China wholesale Filling Capping And Labeling Machine - Horizontal Labeling Machine – Brightwin

China wholesale Filling Capping And Labeling Machine - Horizontal Labeling Machine – Brightwin Detail:

Filling Machine

Introduction:

This machine is used to fill various liquid and viscous products, juice, beverage etc. It adopts piston pump filling with servo motor driven which is more accurate and easy to adjust the volume.

Parameter:

| program | Beverage filling line |

| Filling head | 2, 4, 6, 8, 10, 12, 16 etc(optional according to speed) |

| Filling volume | 1-5000ml etc(customized) |

| Filling speed | 200-6000bph |

| Filling precision | ≤±1% |

| Power supply | 110V/220V/380V/450V etc(customized) 50/60HZ |

| Power supply | ≤1.5kw |

| Air pressure | 0.6-0.8MPa |

| Net weight | 450kg |

Screw Capping Machine

Introduction:

The interactive screw capping machine is the new product developed by our company. It adopts magnetic moment capping head to screw the caps and manipulator to place caps, which is more accurate and stable than common machine. The manipulator work achieve through cam. Clutch is equipped, if any bottle blocked, the starwheel would stop automatically. It is practical, and the ideal equipment in such industries like pharmacy, food, chemical industry etc.

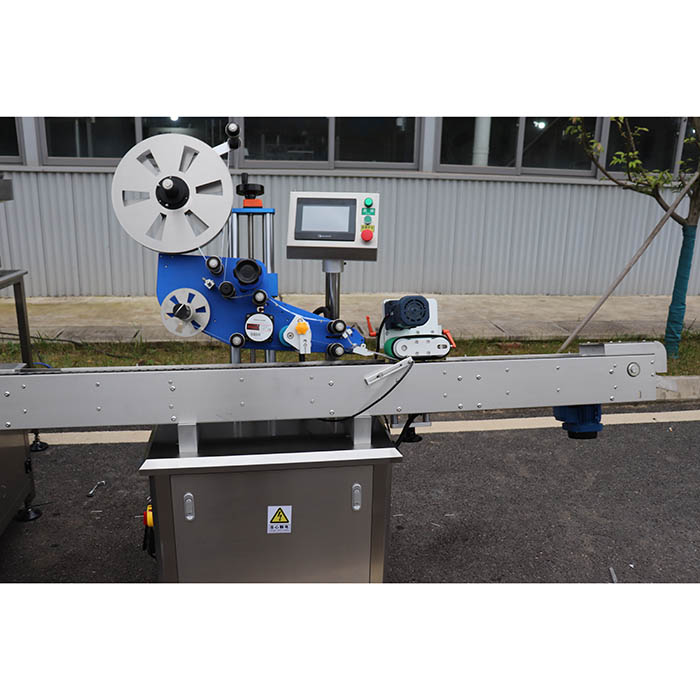

Double Side And Round Bottle Labeling Machine

Introduction:

This double side labeling machine is used to label both flat or square bottles and round bottles. It is economical, and easy to operate, equipped with HMI touch screen & PLC Control System. Built in microchip makes fast and easy adjustment and changeover.

Specifications:

| Speed | 20-100bpm( related to product and labels) |

| Bottle size | 30mm≤width≤120mm;20≤height≤400mm |

| Label size | 15≤width≤200mm,20≤length≤300mm |

| Labeling issuing speed | ≤30m/min |

| Accuracy(excluding container and label’s error ) | ±1mm (excluding container and label’s error ) |

| Labels materials | Self-sticker, not transparent (if transparent, it needs some extra device) |

| Inner diameter of label roll | 76mm |

| Outer diameter of label roll | Within 300mm |

| Power | 500W |

| Electricity | AC220V 50/60Hz single-phase |

| Dimension | 2200×1100×1500mm |

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for China wholesale Filling Capping And Labeling Machine - Horizontal Labeling Machine – Brightwin , The product will supply to all over the world, such as: Romania, Madras, San Diego, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.