Good Quality Automatic Bottle Unscrambler – Brightwin wash solution buffer filling line for a customer from Saudi Arabia – Brightwin

Good Quality Automatic Bottle Unscrambler – Brightwin wash solution buffer filling line for a customer from Saudi Arabia – Brightwin Detail:

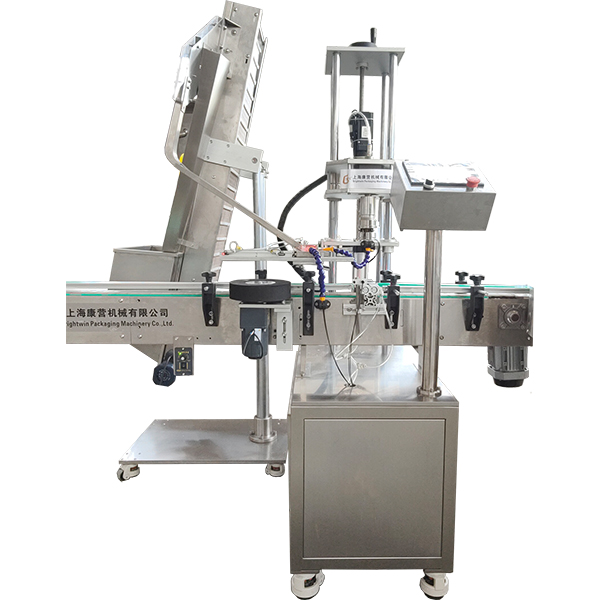

Washe solution buffer servo filling elevator feeding caps servo screw capping machine line. The whole line was assembled bottle feeding turntable and collection turntable to be an automatic packaging line.

Workers place empty bottles on the turntable, through the rotating of the table, bottles will rotate with it, guide bar will guide bottles to the outlet track one by one.

The line is adjustable for many different shape and size containers. This 4 nozzles servo filling machine fills 4 bottles at the same time, also can be used as any other automatic liquid filling machine, like oil filling machine, etc.

Since customer’s bottle have same caps, we used vibrator to feed caps to save customer’s cost. Capping head is movable, when a cap is ready, capping head goes catch it, and back to origin position to wait for filled bottles, once a bottle arrives, capping head down and screw the cap tightly on the bottle mouth.

Finished bottles come with conveyor, will be collected in this turntable, waiting for workers to do next packaging movement.

| Program | Liquid filling machine |

| Filling nozzle number | 4 |

| Capacity for 30ml bottles | 30bpm |

| Capacity for 125ml bottles | 30bpm |

| Accuracy | ≤±1% |

| Air pressure | 0.6-0.8MPa |

| Voltage | 220V Single phase |

| Power | 3KW |

The line is ready to go, waiting for customer’s arrangement!

Product detail pictures:

Related Product Guide:

We support our buyers with ideal high quality products and high level service. Becoming the specialist manufacturer in this sector, we have gained rich practical experience in producing and managing for Good Quality Automatic Bottle Unscrambler – Brightwin wash solution buffer filling line for a customer from Saudi Arabia – Brightwin , The product will supply to all over the world, such as: Mauritius, Myanmar, Swaziland, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

We have been looking for a professional and responsible supplier, and now we find it.