Manufacturer for Adhesive Sticker Labeling Machine - Double Side Labeling Machine – Brightwin

Manufacturer for Adhesive Sticker Labeling Machine - Double Side Labeling Machine – Brightwin Detail:

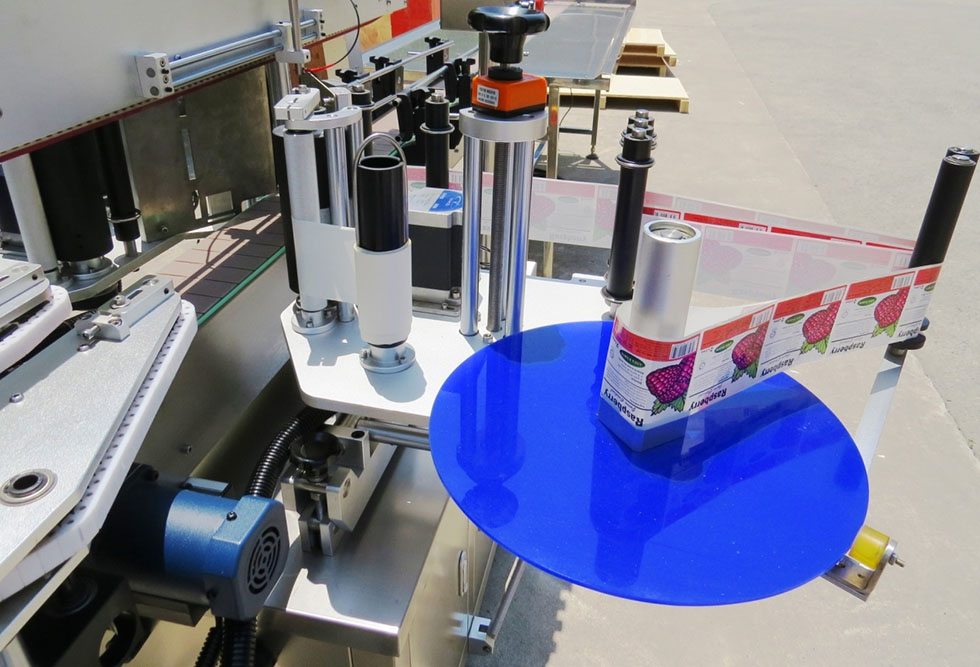

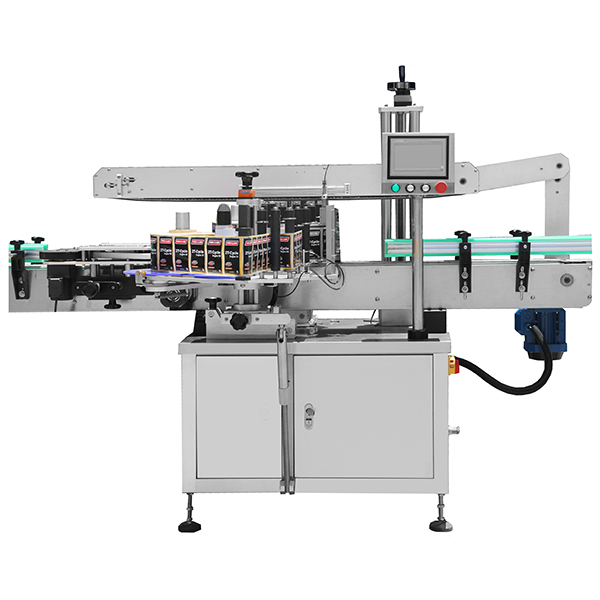

Double side labeling machine

This double side labelingmachine is used to label both flat or square bottles and round bottles. It is economical, and easy to operate, equipped with HMI touch screen & PLC Control System. Built in microchip makes fast and easy adjustment and changeover.

| Speed | 20-100bpm( related to product and labels) |

| Bottle size | 30mm≤width≤120mm;20≤height≤350mm |

| Label size | 15≤width≤130mm,20≤length≤200mm |

| Labeling issuing speed | ≤30m/min |

| Accuracy(excluding container and label’s error ) | ±1mm (excluding container and label’s error ) |

| Labels materials | Self-sticker, not transparent (if transparent, it needs some extra device) |

| Inner diameter of label roll | 76mm |

| Outer diameter of label roll | Within 300mm |

| Power | 500W |

| Electricity | AC220V 50/60Hz single-phase |

| Dimension | 2200×1100×1500mm |

➢ Principle: After separating system the bottles, sensor detects it and give signal to PLC, the PLC will order motor to put the labels on the suitable position on the labeling head to label the bottles when bottles pass.

➢ Process: bottle entering—> bottle separating—>bottle detecting—>label issuing—>labeling—>bottle existing.

Advantages

➢ Wide function, can be used for front and back labels on flat, square and strange shape bottles.

➢ High accuracy. With deviation correcting device for labeling to avoid label deviating. Stable performance, excellent labeling result without wrinkles and bubbles.

➢ Stepless motor for speed adjusting on labeling conveyor, bottle separating.

➢ Double side synchronous directing chains special for flat, square and cambered surface bottles to make sure the bottles automatically centralized, reducing the difficulty of manual bottle loading on the machine and automatic bottle entering in production line.

➢ Equipped with top pressing device to make sure bottles move stable reducing the errors caused by bottle height differences.

➢ Flexible usage. Labeling on stand-up bottles, equipped with bottle separating function. The machine can be used solely or connected to automatic line.

➢ Twice labeling device, one for accuracy, another for eliminating bubbles and making sure labels tightly stuck from heads and tails.

➢ No bottles no labeling, self-inspection and self-correction for no labels situation.

➢ Alarming ,counting, power saving (If no production during fixed time (the machine will turn to power saving automatically), specification setting and protecting function ( authority limits for specification set).

➢ Durable, adjusting by 3 poles, taking advantage of stability from triangle. Made or stainless steel and high quality aluminum, conforming to GMP standard.

➢ Original design for mechanical adjusting structure and labeling rolling. The fine adjusting for freedom of motion in label position is convenient( can be fixed after adjusting), making easy the adjustment and winding labels for different products,

➢ PLC+ touch screen + stepless motor + sensor, save working and control. English and Chinese version on touch screen, error reminding function. With detailed operation instruction including structure, principles, operations, maintenance and etc.

➢ Optional function: hot ink printing; automatic material supply/ collecting; adding labeling devices; circle position labeling, and etc.

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service

Product detail pictures:

Related Product Guide:

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for Manufacturer for Adhesive Sticker Labeling Machine - Double Side Labeling Machine – Brightwin , The product will supply to all over the world, such as: Gabon, Iraq, Canada, We now have to continue to uphold the "quality, detailed, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.