What should be considered at the beginning of the olive oil filling production line project?

1. How many bottles need to be filled per hour?

2. What is the volume of the bottle?

3. Better dont have too many types of caps, otherwise there will be more replacement parts for production machines.

4. You can communicate with the machine manufacturer if you need know the space dimension, and Brightwin, a machine manufacture with experience, can provide it for you.

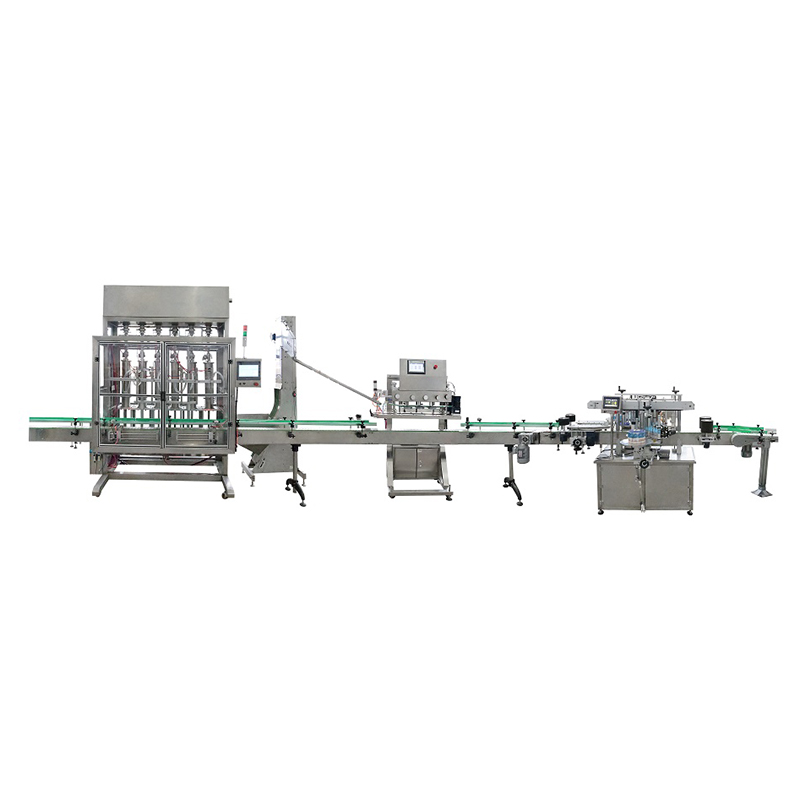

How to choose olive oil filling production line?

1. Many people choose olive oil filling production lines and prefer to find cheaper ones, but is it really cheap?

The cost that needs to be considered is not only the cost for the purchase of the machine, but also some other effects caused by this machine.

1) Can the quality of cheap machines be guaranteed?

Just like we buy clothes, are clothes for 10 dollars the same as clothes for 100 dollars? The answer can be imagined. Clothes for $100 need to buy better raw materials, need to be equipped with skilled workers, more stringent production procedures, and more precise production machines. In the same way, poor-quality machines and good-quality machines cannot be the same price.

In addition, the production process of poor quality machines will inevitably cause frequent failures. After that, production will be stopped first, and product supply cannot be guaranteed. And need to invest in repairman labor costs and material replacement costs.

Machines are also alive. Machines that frequently break down are like people who constantly perform operations. The production speed and production quality cannot be guaranteed during daily use. The service life of the machine will also be greatly reduced.

The quality of Brightwin’s machines is very reliable, using the best materials, and the best accessories such as MITSUBISHI, SCHNEIDER, OMRON ETC, to ensure the normal production of customers and longer use time than other factories’ machines.

2. Please choose a manufacturer to buy olive oil filling machine

Brightwin is a very experienced manufacturer and has been making olive oil filling machines for more than 20 years. The engineers are very experienced, the machines are exquisitely made, and they have encountered various customer requirements, such as special bottles, special caps or fast production speed. However, the engineers have helped the customers solve the problems and ensured Customer’s production. I have been very experienced in making olive oil filling machines. That is the advantages of manufacture for olive oil filling machine, can make olive oil filling machine according to the needs of customers.

3. Please pay attention to the following machine details when purchasing olive oil filling machine.

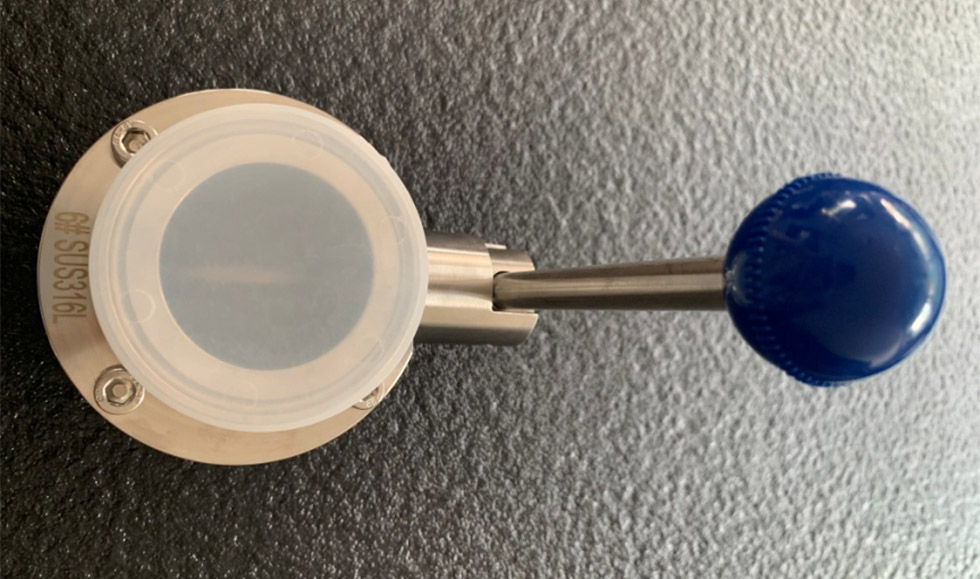

Sealing ring in our liquid filling machine

1. It is imported from Germany. It is composed of stainless steel spring and UPE (ultra high molecular weight polyethylene).

2. Withstand temperature range: -200 ℃ to 300 ℃.

3. Low friction coefficient (especially under the high working pressure).

4. High pressure resistance, excellent sealing performance under high or low pressure.

5. High Wear-resistant without leakage and corrosion resistant.

It is made of stainless steel 306, and it is specially designed which is much longer than common filling nozzles, so it can protect the cylinder on top being damaged.

Filling nozzles and valves in our liquid filling machine

With detector in each filling nozzle or valve, so if there is any problem in any nozzle or valve, it would shows on touch screen, and we can find the problem very easily.

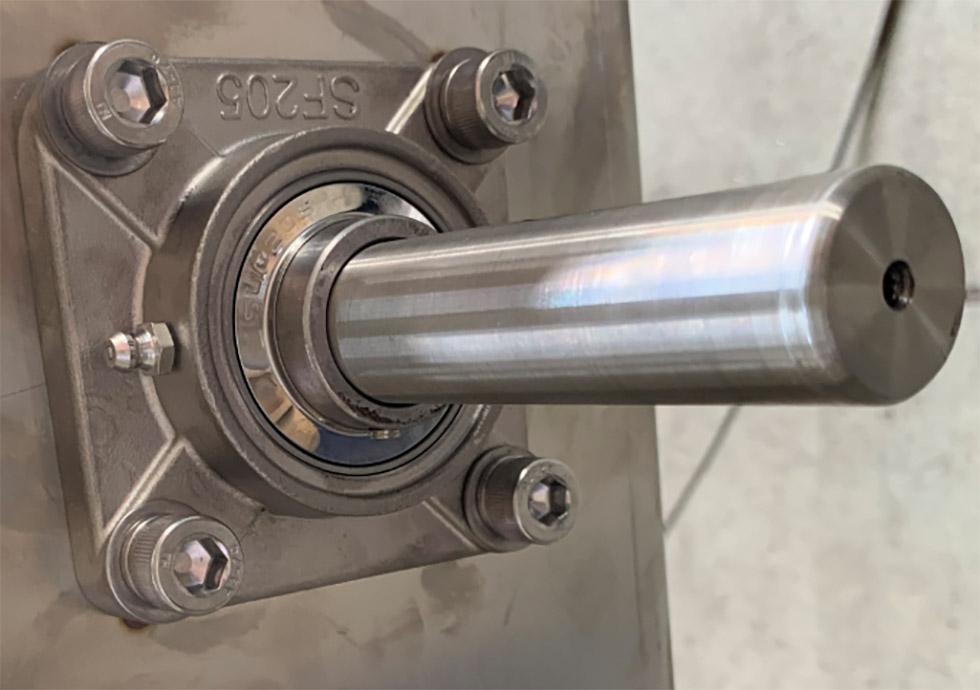

Piston cylinder in our liquid filling machine

It is made of 5mm-5.5mm thick SUS316L, and it is honed, which is more smooth without leakage.

Servo motor in our liquid filling machine

The filling machine is servo motor controlled, which is more accurate and easy to adjust the volume. The brand of servo motor is Mitsubishi.

Post time: Nov-04-2021