In China, there are many many packaging machinery manufacturers, so when the customers are trying to find a trustworthy supplier, they are confused and its very hard for them to make the decision. Now we want to show you some of our machines details, hoping that we can help you know more about our machines and help you how to judge the machine is good or not. We will take our liquid filling machine as an example.

This liquid filling machine can be used to fill various liquid products, like edible oil, beverage, liquid soap, and lube oil etc. The following are the details of the machine:

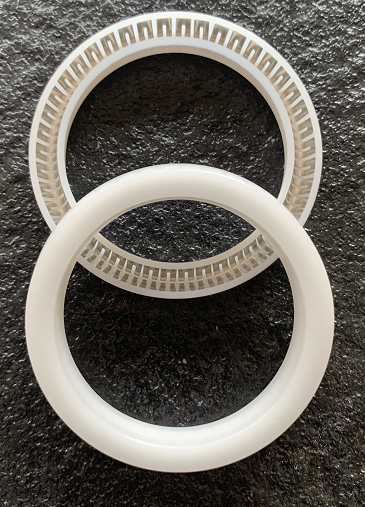

Sealing ring in our liquid filling machine

1. It is imported from Germany. It is composed of stainless steel spring and UPE (ultra high molecular weight polyethylene).

2. Withstand temperature range: -200 ℃ to 300 ℃.

3. Low friction coefficient (especially under the high working pressure).

4. High pressure resistance, excellent sealing performance under high or low pressure.

5. High Wear-resistant without leakage and corrosion resistant.

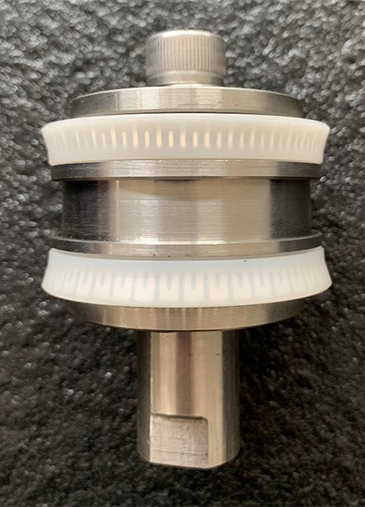

Filling nozzle in our liquid filling machine

It is made of stainless steel 306, and it is specially designed which is much longer than common filling nozzles, so it can protect the cylinder on top being damaged.

Filling nozzles and valves in our liquid filling machine

With detector in each filling nozzle or valve, so if there is any problem in any nozzle or valve, it would shows on touch screen, and we can find the problem very easily.

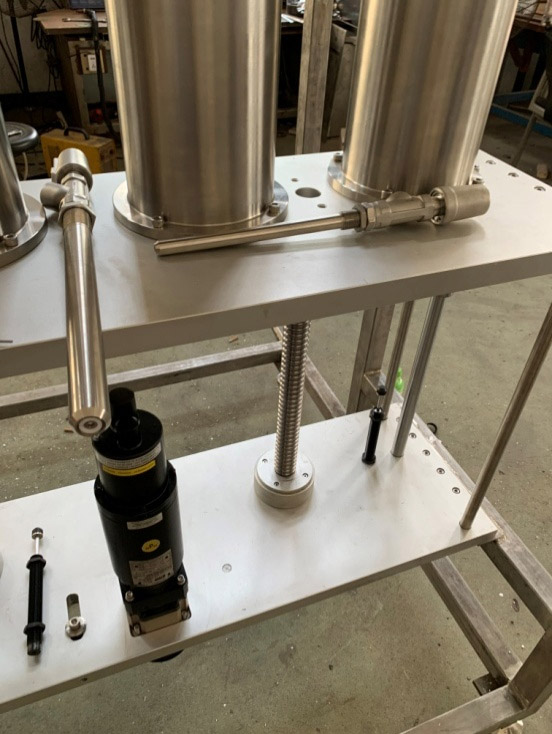

Piston cylinder in our liquid filling machine

It is made of 5mm-5.5mm thick SUS316L, and it is honed, which is more smooth without leakage.

Servo motor in our liquid filling machine

The filling machine is servo motor controlled, which is more accurate and easy to adjust the volume. The brand of servo motor is Mitsubishi.

Connecting pipe in our liquid filling machine

In our machines, even the connecting pipes are made of stainless steel 316, while most of other suppliers use stainless steel 304.

Seamless safety cover in our liquid filling machine

There are covers on both front and back of our filling machines, while there is only cover in front, and even no cover in the machines from some of other suppliers.

Piston pump base plate in our liquid filling machine

25mm thick whole piece of stainless steel plate, which is more stable and longer service life. While it is 15mm single pieces of stainless steel plate from other companies.

Mounting plate in our liquid filling machine

25mm thick whole piece of stainless steel plate, which is more stable and longer service life. While it is 15mm single pieces of stainless steel plate from other companies.

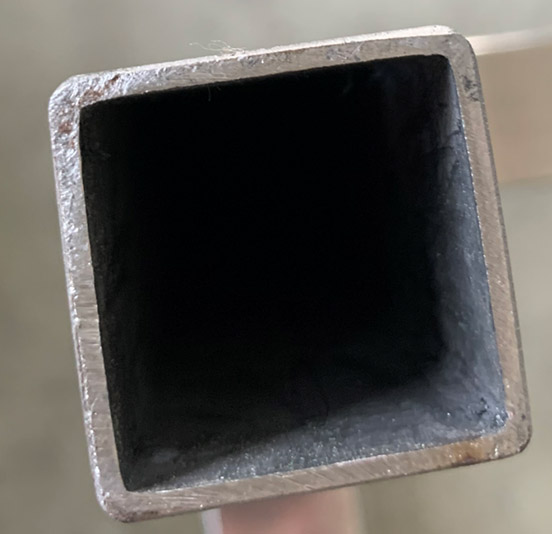

Frame in our liquid filling machine

Thickness 2mm frame flat pipe, its more stable, which its only 1.2mm from most of other suppliers.

Servo motor synchronous belt in our liquid filling machine

It is 5mm wide, while its 2mm wide for the machines from other suppliers.

Axis in our liquid filling machine

SUS304 axis for conveyor wheel, while its Iron with painting from most of other companies

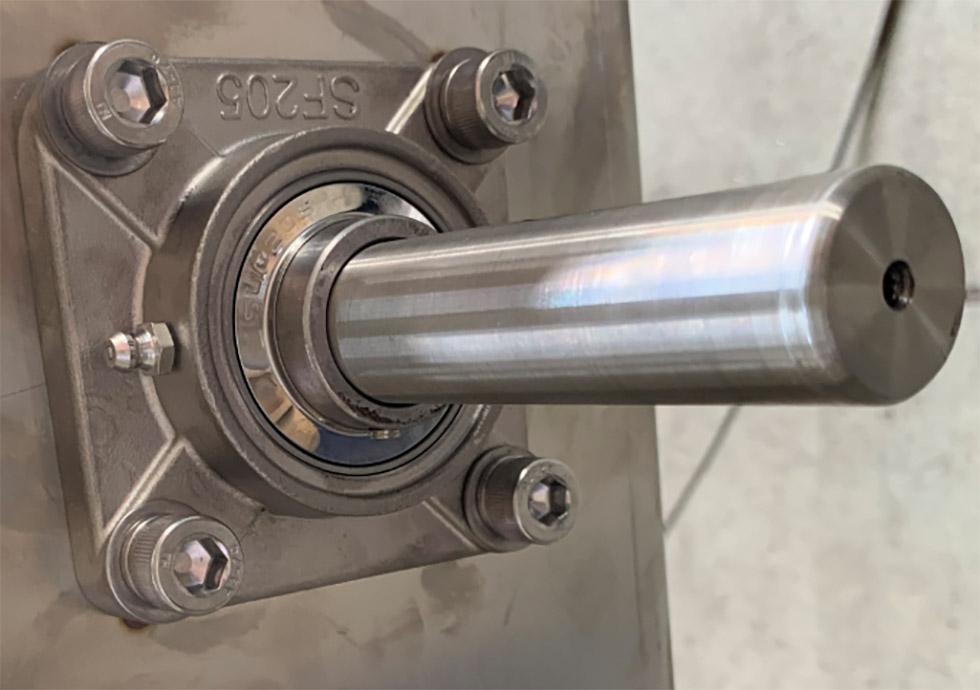

Flange seat in our liquid filling machine

SUS304 flange seat for conveyor wheel, while its Iron with painting from most of other companies

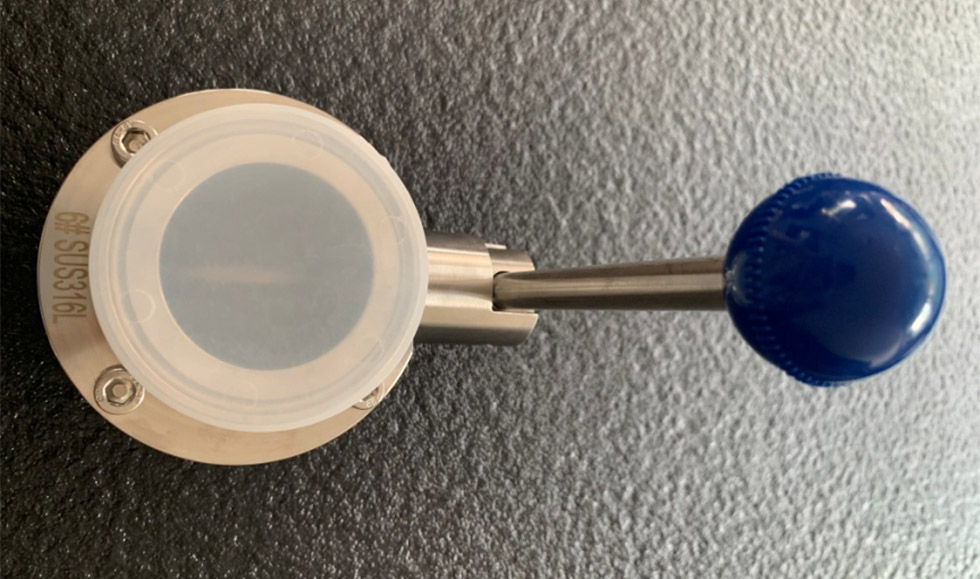

Connecting valve in our liquid filling machine

SUS316L connecting valve, while SUS304 from most of other companies

Post time: Aug-28-2021