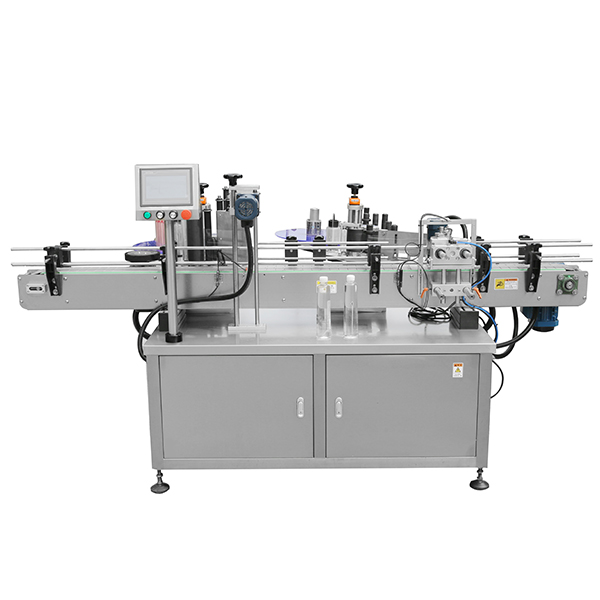

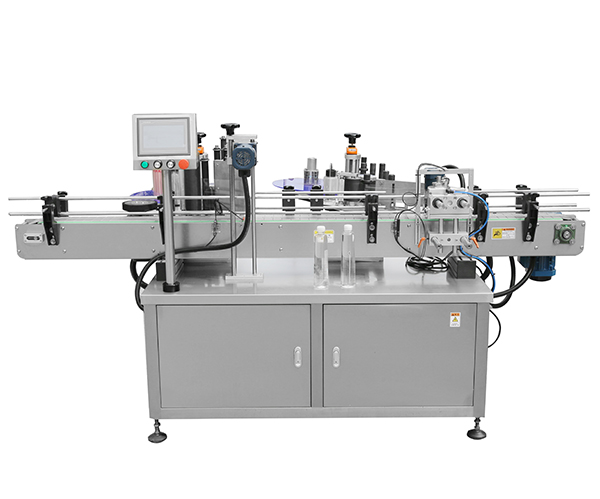

Round Bottle Labeling Machine

Round bottle labeling machine

This round bottle labeling machine is suitable for all kinds of round bottles/ jars/ cans etc. Both glass bottles and plastic bottle are ok. Also the machine is adjustable to suit different diameter and height bottle.

|

Driven |

Step motor |

|

Direction |

Right to left/ Left to right |

|

Label core |

Standard 75mm |

|

Label roll |

Max 300mm |

|

Bottle size |

Diameter: 10-150mm Height 3-350mm |

|

Label size |

Length 10-3500mm Width 10-200mm |

|

Precision |

±0.5mm |

|

Hot ribbon coding |

HP 260Q |

|

Power |

220/380V 50/60Hz 350W |

|

Weight |

200kg |

|

Machine size |

1500*850*1200mm(L*W*H) |

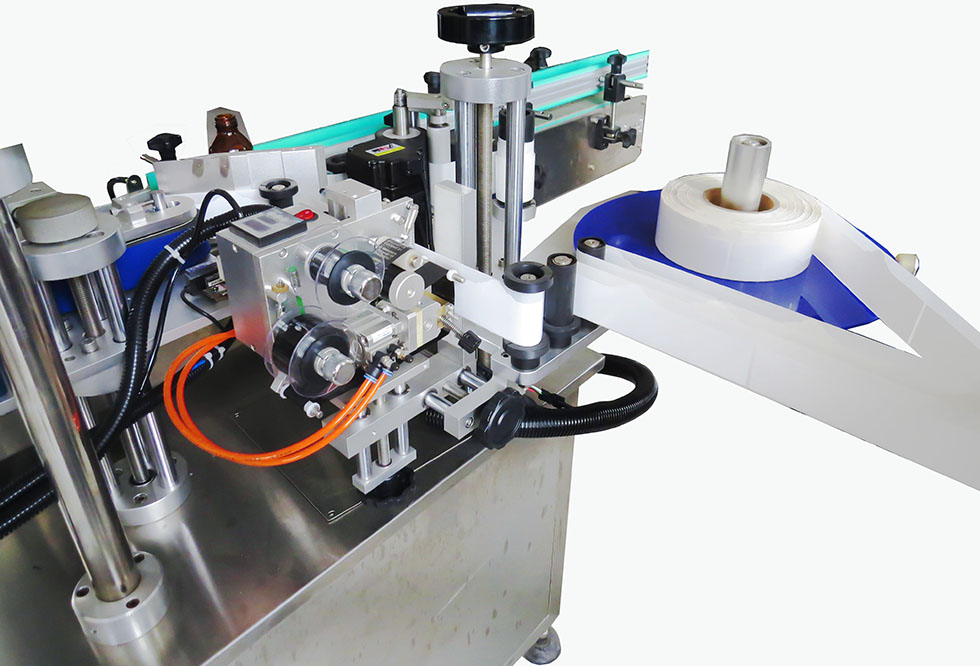

Belt Type Conveyor

This labeler use imported industrial belt. It is much wearable without dirty easily and for long term life operation. It also could change over the suitable belt material depends on products.

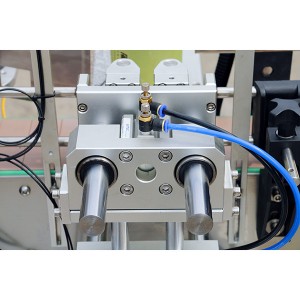

Precise Sensor

Adopt to top level fiber optic sensor to precisely do products and label location without interference. Unique design for slide rail, it is much different from the poor design by general manufacturer.

Quality & Beauty

The labeler main structure is manufactured from S304 stainless steel with anodized process and high quality aluminum. It is complied with GMP standard that provides easy maintenance and for a long durable life. Top chain made by FRP chain material and hard-wearing UPE guide rail applied for the conveyer system is designed to be the product appearance protected and efficient performance. It also increases with years of reliable long term use.

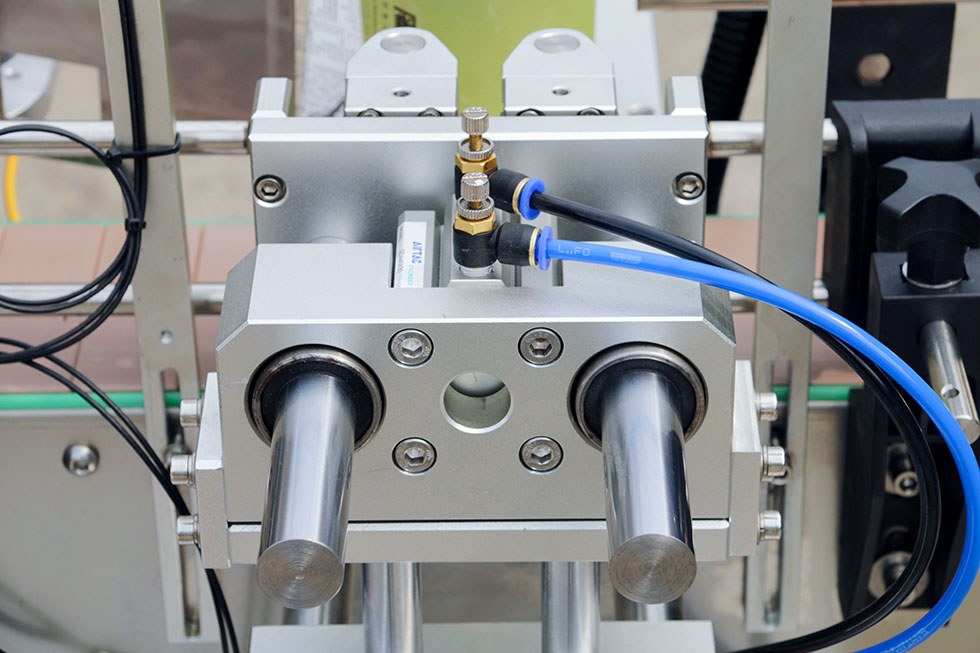

Simple Mechanism Adjustment

It provides a little or big wide adjustment by equipped with hand wheel mechanism for easy adjustment of applicator. It would also provide flat and smooth labeling depended on product sizes and labeling position by suitable wrap station adjustment.

Rigid Machine Base

Double square foot stands was made from stainless steel. It is steady and does not take a lot of room. When labeler working, it would not quake and affect the labeling action.

Flexible Mobility

The mobility castor and stainless steel fixing nut are designed to flexibly move the machinery to support another production line. Therefore, it would boost the invest benefits.

Optional

If need, can equip a code printing machine to print production date etc onto the label.

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service