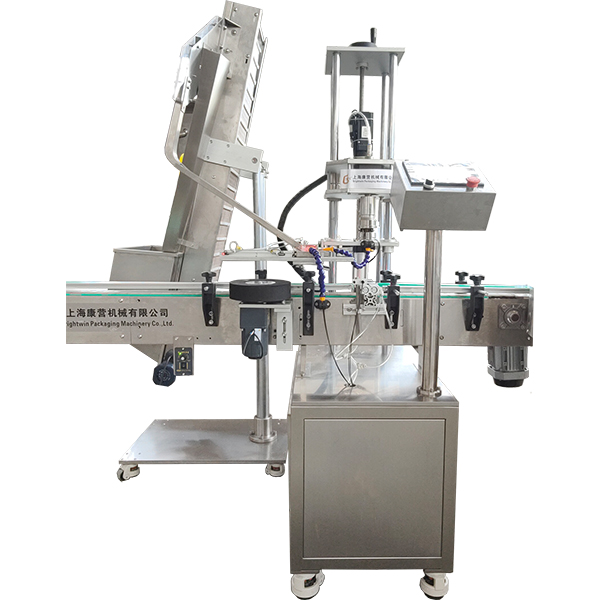

Servo screw capping machine

Servo screw capping machine

The machine adopts sensors to detect caps and bottles. Caps feeding and bottles feeding work at the same time, when one cap is detected by the sensor, screw capping head comes down grab it to standby, when one bottle is detected by the sensor, screw capping head comes down to screw the cap tightenly on the bottle mouth.

All the parameters can be setted on Touch screen, like speed, torque, delay time, etc.

Workers just need to place a certain amount caps into caps feeding device's hopper, then repeat this action periodically.

● Servo motor control the torque to avoid caps' damage.

● This machine is for the caps 10mm-100mm regardless the shapes as long as screw caps. (Can be customized)

● This machine can be used for special shape caps, like: spray head, "duck mouth" shape head, and "gun" shape head, etc. (Can be customized)

● This machine can be used some special situation, like: bottle's handle higher than bottle mouth, caps are difficult to be placed on bottle mouth, etc.

● This machine has the original design, easy to operate and adjust.

● The speed can reach 30bpm, freely used separately or combined into production line.

● You can choose the cap feeder to make it fully automatic (ASP). We have the cap elevator, cap vibrator, declined plate and etc. for your choice.

| Caps diameters | 10-100mm(customized) |

| Bottle diameters | 10-150mm(customized) |

| Driver | Servo motor |

| Screw speed | 0-1000r/min |

| Capacity | 0-30bot/min |

| Voltage | 220V, single phase(customized) |

| Screw torque | Adjustable |

Glass cover

Whether the glass cover needs to be added, up to you.

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service