Short Lead Time for Bottling Line Equipment - Filling Machine – Brightwin

Short Lead Time for Bottling Line Equipment - Filling Machine – Brightwin Detail:

Filling machine

This machine is used to fill various liquid, viscous liquid or thick liquid products, like cooking oil, lube oil, beverage, juice, sauce, paste, cream, honey, shampoo, detergent, pesticides, and Liquid fertilizer etc as long as it can flow. It adopts piston pump filling with servo motor driven which is more accurate and easy to adjust the volume. With rotary valve for thick or viscous liquid products and non-rotary valve for liquid products

Parameter

|

program |

filling machine |

|

Filling head |

2, 4, 6, 8, 10, 12, 16 etc(optional according to speed) |

|

Filling volume |

1-5000ml etc(customized) |

|

Filling speed |

200-6000bph |

|

Filling precision |

≤±1% |

|

Power supply |

110V/220V/380V/450V etc(customized) 50/60HZ |

|

Power supply |

≤1.5kw |

|

Air pressure |

0.6-0.8MPa |

|

Net weight |

450kg |

Elements brand

|

Item |

Brands and material |

|

sensor |

Omron |

|

PLC |

SIEMENS |

|

Touch screen |

SIEMENS |

|

Servo motor |

Mitsubishi |

|

Piston cylinder |

5MM thick SUS316L |

|

Rotary valve |

SUS316L |

|

Rotary valve connection |

quick coupler designed from Germany |

|

Filling nozzles |

SUS316L stainless steel anti-drip quick-coupler design |

|

Cylinder |

Airtac Taiwan |

|

Connecting pipe |

fast loading pipe from Italy |

|

Sealing ring |

food grade material from Germany |

|

electrical parts |

Schneider |

|

Rack |

SUS304 |

|

bearings |

Japan NSK, original imported |

|

Level control in hopper |

with |

1. The material of sealing ring is imported from Germany. It is composed of stainless steel spring and UPE (ultra high molecular weight polyethylene).

2. Equipped with SUS316L long sepcial designed no–drip filing nozzles, which can protect the cylinder on the top being damaged by material. As following pictures:

3. 304 frame, 5mm thick SUS316L honing piston pump, manufactured by Taiwan producer

4. With detector in each SUS316L valve and filling nozzle, if there is any problem in any nozzle, it shows in touch screen, its easy to be found.

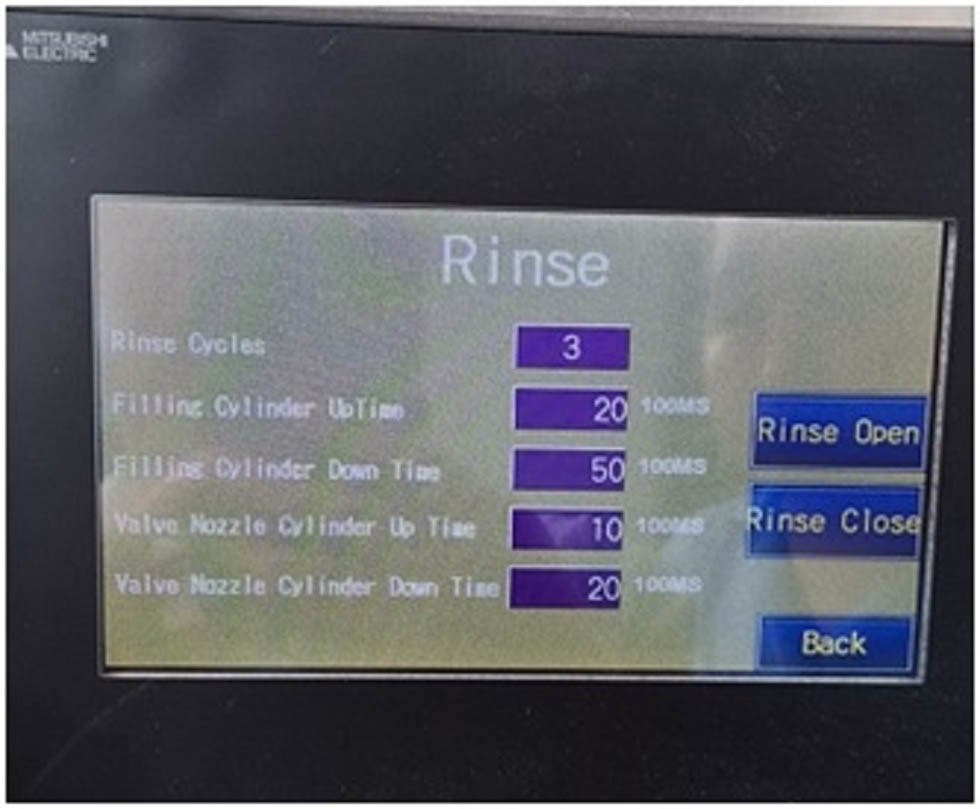

5. With automatic cleaning system

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for Short Lead Time for Bottling Line Equipment - Filling Machine – Brightwin , The product will supply to all over the world, such as: azerbaijan, Japan, Poland, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.