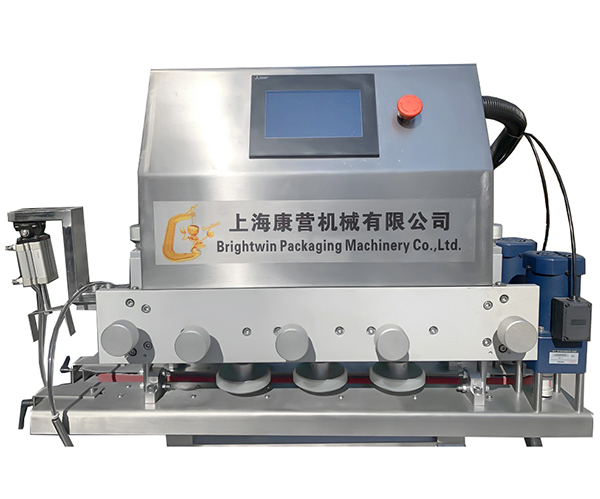

Spindle Capping Machine

Spindle capping machine

● 'one motor controls one capping wheel', which can ensure the machine to work stably and keep consistent torque under long term working condition.

● Easy to operate.

● Mitsubishi PLC and touch screen control, easy to operate.

● The gripping belts can be adjusted separately to coordinate with different bottles.

● If equipped with guidance device, the machine can cap the pump caps.

● Rulers on every adjusting parts to make the adjustment "visible".

● The torque limiter is optional to make sure the consistent torque.

● The up-down motor is optional to make the machine go up and down automatically.

● This machine is for the caps 10mm-100mm regardless the shapes as long as screw caps. This machine has the original design, easy to operate and adjust. The speed can reach 200bpm, freely used separately or combined into production line.

● When you use semi-automatic spindle capper, the worker only needs to put the caps onto bottles, during their moving forward, the 3 groups or capping wheels will tighten it.

● You can choose the cap feeder to make it fully automatic (ASP). We have the cap elevator, cap vibrator, declined plate and etc. for your choice.

Caps diameters: 10-100mm

Bottle diameters: 10-150mm

Bottle gripping speed: 0-17.4m/min

Spindle wheels speed: 0-18.5m/min

Productivity: 50-200bot/min

Power supply: 220V, single phase

Wheel torque: 10-70N*m

1. Offer professional operation manual

2. Online support

3. Video technical support

4. Free spare parts during warranty period

5. Field installation, commissioning and training

6. Field maintenance and repair service